Broaching What Is It? How Does It Work? Types, Products

Broaching is classified into two types: linear and rotary. The broach is run linearly against the surface of the workpiece to effect the cut in linear broaching, which is the more common process. Linear broaching Linear broaches are used in a broaching machine, which is also abbreviated as a broach.

Hex Spline Square ‘D’ Double D Oval Circles

There are two principal types of broaching machines: horizontal and vertical. In addition to these standard types, there are special and continuously operating machines. Both horizontal and vertical types of machine have one or more rams depending on production demand.

Broach

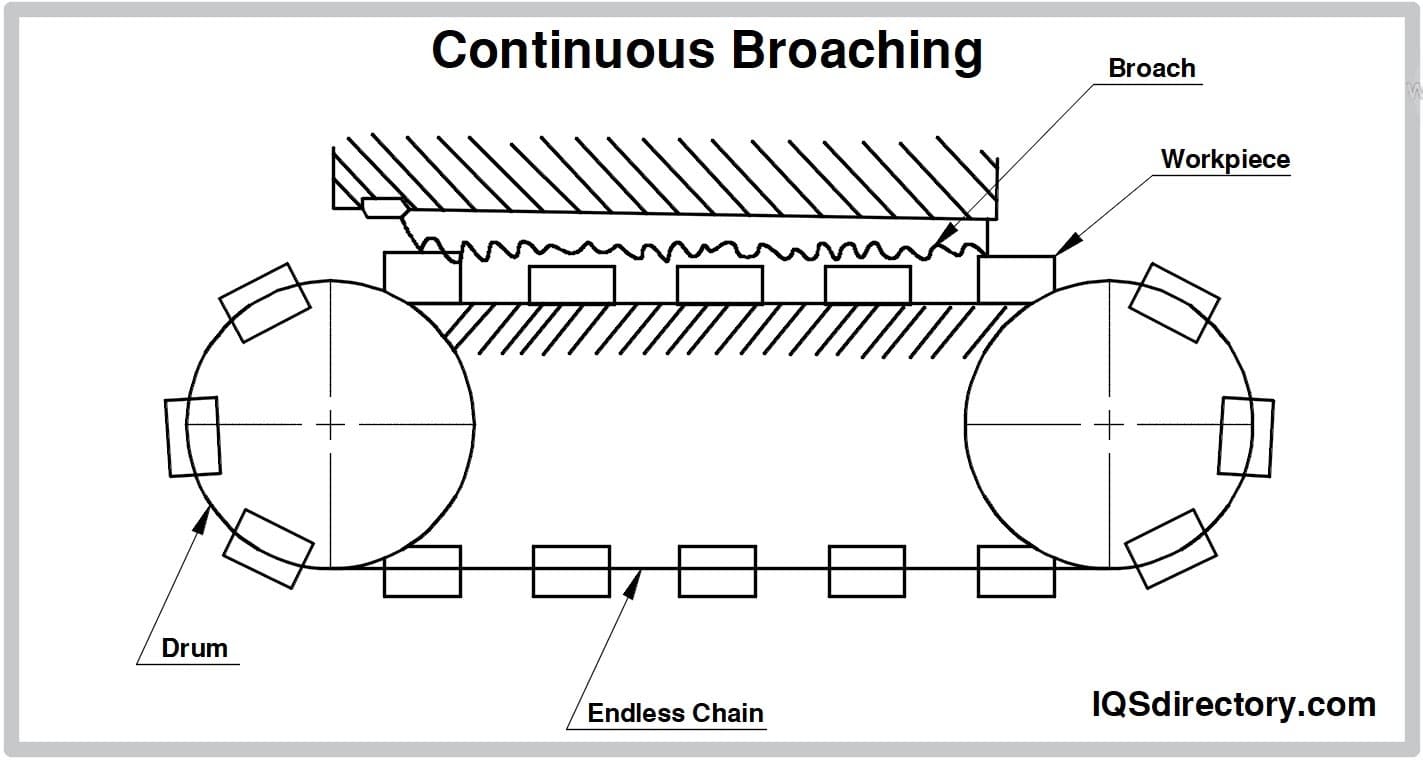

In contrast, chain-type broaching machines allow continuous external machining of workpieces, such as screw wrenches, feet of rotor blades, and brake calipers for disk brakes. One chain-type broaching machine can replace multiple external broaching machines and is easy to automate. Broaching machines are driven either electrically or hydraulically.

Broach and types of broaches Informational Encyclopedia

There are two principal kinds of broaching machines: - horizontal and vertical. Notwithstanding these standard types, there are unique and constantly operating machines. Both horizontal and vertical sorts of the machine have at least one ram relying upon production demand.

What is? How does it work? types, products (2023)

Types of Broaching Machines. Broaching machines are used to create a uniform width of cut across the top surface of the material being processed. These machines have been around since the early 1900s and were originally designed to make flat surfaces on metal parts. Today, they are still widely used in many industries, including woodworking.

What is Broaching? Broach Tools. Broach Elements, Part 1

The two types of broaching machines are horizontal and vertical; they can have one or more rams depending on the application. With dual or multiple rams, the rams work opposite each other, with one on the cutting stroke and the other on the return stroke. A broaching machine either pulls or pushes the broach through or past a held workpiece.

What is Broaching? Broaching Machines & Types

There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to produce the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to broach.

Production Broaching Los Angeles, CA Pioneer Broach

The broach tool is the vital part of any broaching operation. The tool must be made to the precise size of the final cut desired.. it cannot be coerced or manipulated to cut a size or dimension that it wasn't designed for. Types of Broaches. V W Broaching can manufacture various custom broach toolings to manufacture to keyway broaches.

Broaching (metalworking) Alchetron, the free social encyclopedia

Types of Broaching Linear Broaching Internal Broaching External Broaching Rotary Broaching Surface Broaching Pull Broaching Push Broaching Keyway Broaching Advantages of Broaching High Precision Efficiency Versatility Surface Finish Broaching Applications Automotive Industry Aerospace Industry Medical Equipment Manufacturing Firearms Manufacturing

Broaching Tools Broach Manufacturer Colonial Tool

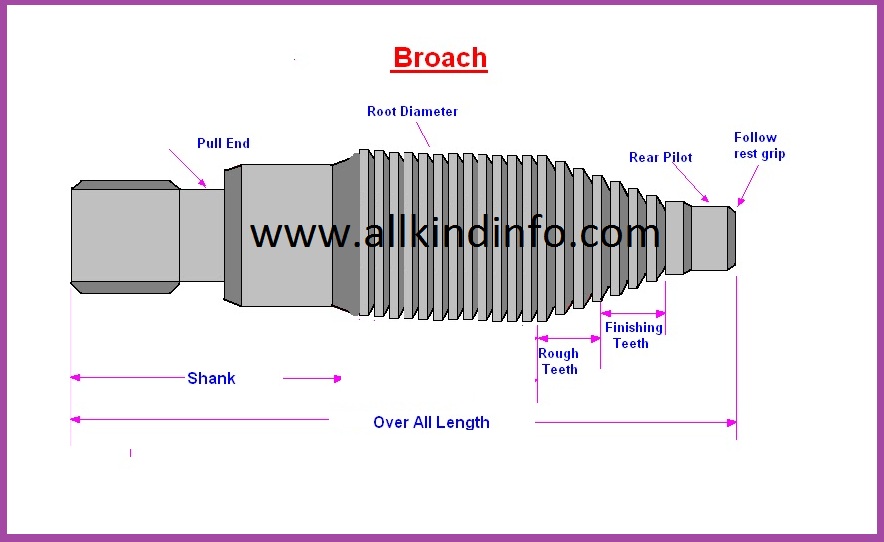

A broach usually has 3 distinct sections: The roughing teeth which remove most of the material The semi finishing teeth provide a surface finish The finishing teeth provide the final finish Broaches can be expensive, costing up to $30,000. This makes broaching a better choice for large quantities of parts.

What is a Broaching? Broaching is a machining process where a sharp, hardened, toothed tool

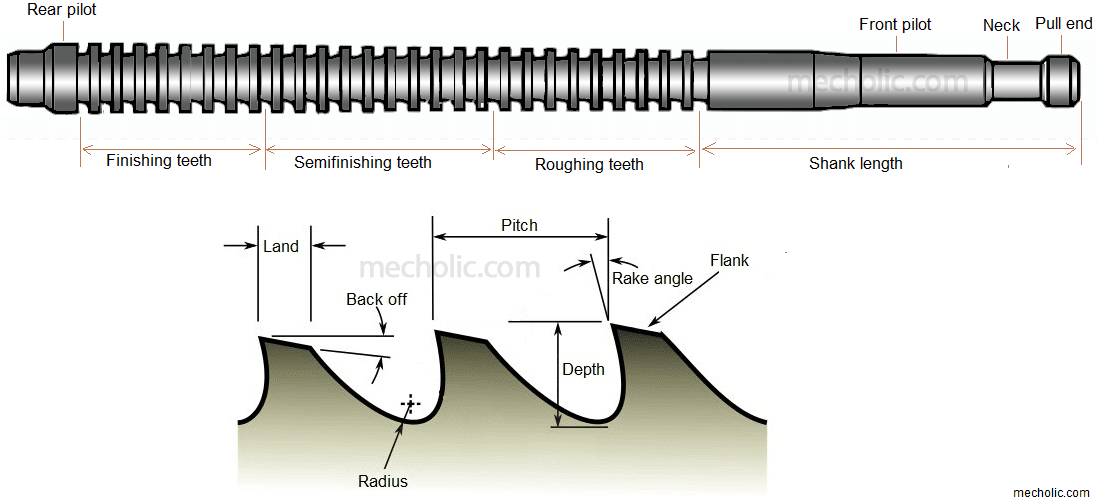

Broach teeth are usually divided into three separate sections along the length of the tool: the roughing teeth, semi-finishing teeth and finishing teeth. The first roughing tooth is proportionately the smallest tooth on the tool. The subsequent teeth progressively increase in size up to and including the first finishing tooth.

Best Top 5 Types Of Broaching Machines.

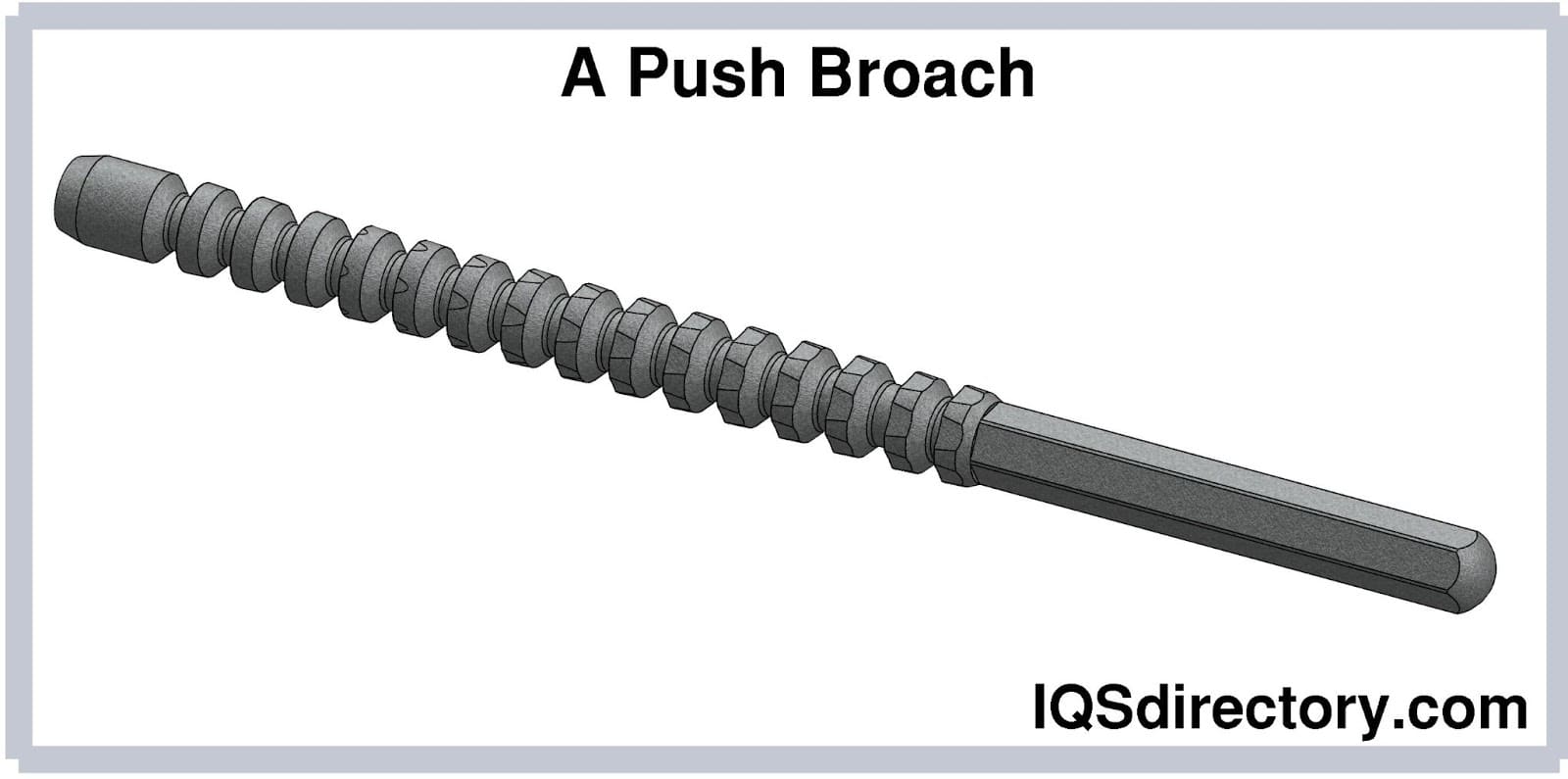

Basic Types of Broaching Tools You can separate most broach tools into two basic categories: push broach and pull broach. Alternatively, you can also divide broaches into internal or external broaching machines. Both push and pull broach tools use similar strategies to machine materials.

Broaching Manufacturer Broaching Companies

There are two main types of broaching: linear and rotary. In linear broaching, which is the more common process, the broach is run linearly against a surface of the workpiece to effect the cut. Linear broaches are used in a broaching machine, which is also sometimes shortened to broach.

broaching tool geometry

Types of Broaches: There is large variety of broaches and they are classified. 1. According to the method of operation: Push, Pull or Stationary. 2. According to the kind of operations they perform: Internal and external. 3. According to their construction: Solid, built up, rotor cut, inserted tooth, over lapping tooth, progressive etc. 4.

Parts of PullType Broach Tool What Is a Broaching Tool? Internal and External Broaching

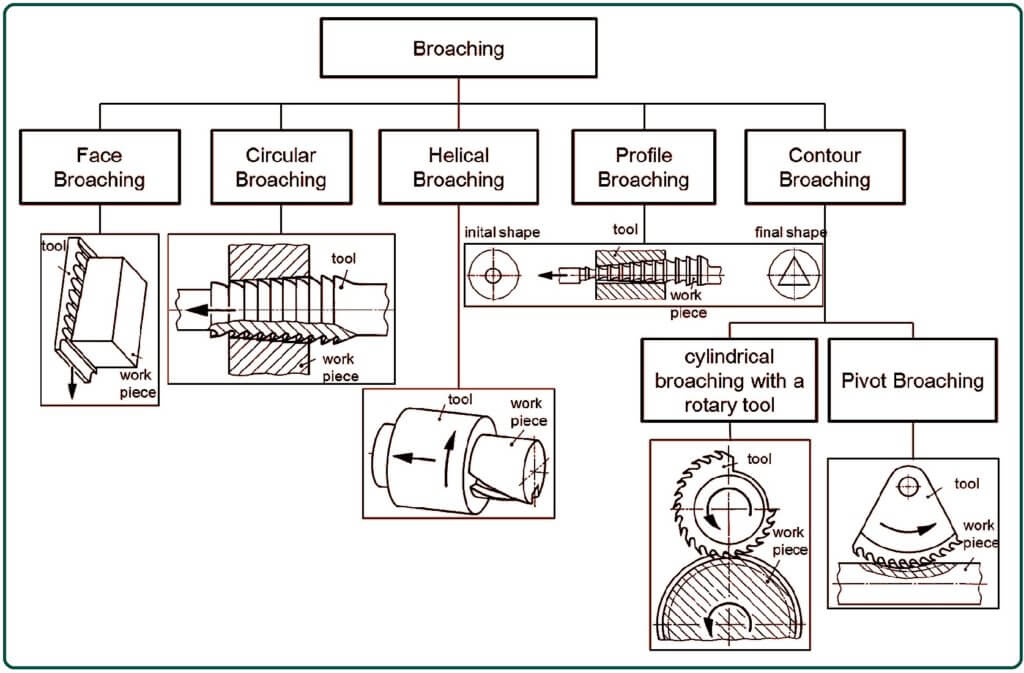

Broaching can be classified into following types: Internal Broaching: Internal broaching is mainly used to enlarge holes. This process generally uses pull type broach but for lighter work piece, it sometime uses push type broach. External Broaching:

What are the Different Types of Broaching Methods? Daily Business Post

Push and pull broaching are two other types of broaching that you can choose from. These two types describe the movement of your broach tools. Your tool is either pushed or pulled into each work-piece. Push broaching requires a short column that can withstand extreme compression without breaking. It's typically used in low-speed applications.