Profibot® 5axis CNC Welding Robots Affordable welding Machines

Efficient 5-axis workholding locates and stabilizes the workpieces without obstructing access to the top and sides of the part, and it also allows a clamped workpiece to be flipped into new orientations for subsequent machining operations without unclamping from the workholding.

cnc 5 axis welding machine YouTube

20 Station Automatic Pallet Changer: Enables the machine to run for approximately 20 hours without an operator if a part has a 1-hour run time, maintaining 5-axis accuracy throughout. Mazak HQR100MSY Multi-Tasking Turning Center: Dual Spindle, Dual Turret with 10,000 RPM Milling Capabilities on both turrets

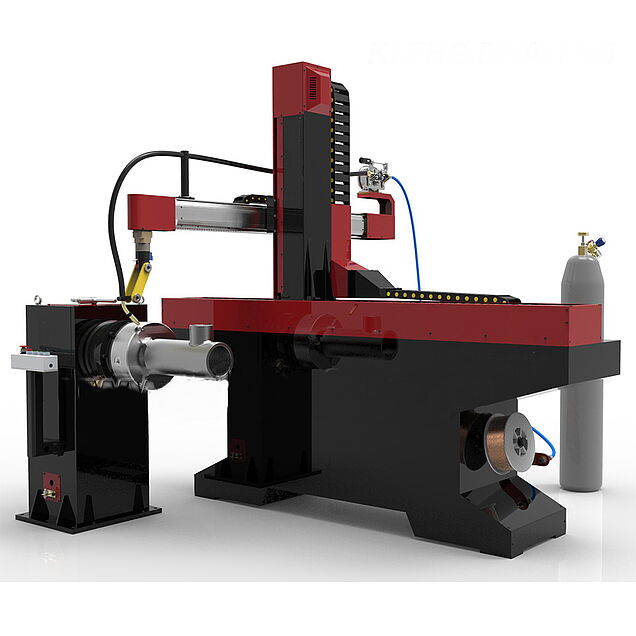

CNC 5 Axis platform flip welding robot workstation KELITE WELD

This video walks you thru setting up a 5 axis trunnion on a 3 axis CNC mill.Setting A axis 2:18Setting Parallel to X axis 3:30Setting X & Y axes 6:08Finding.

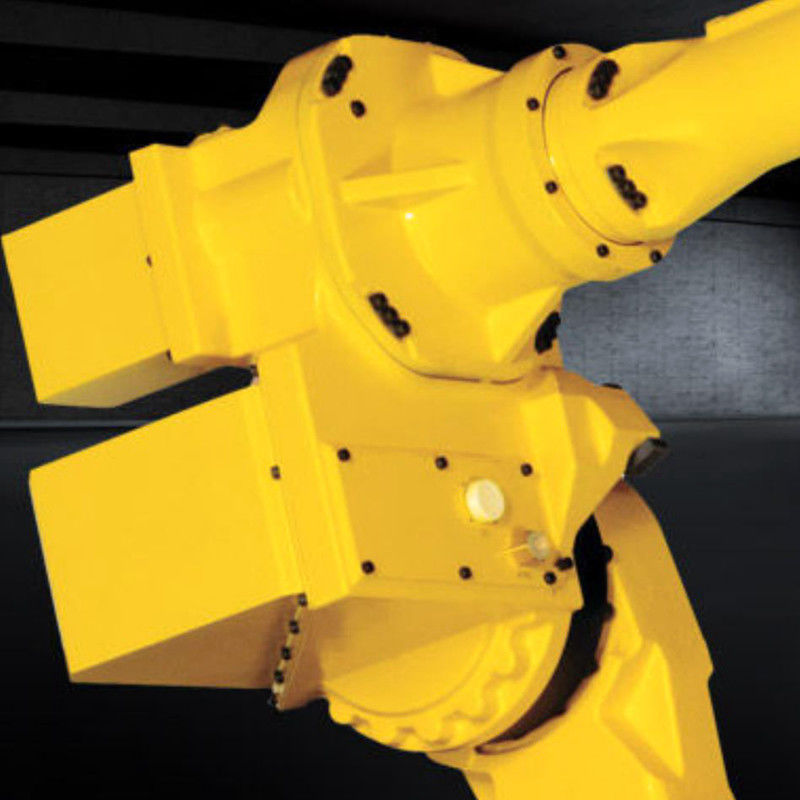

5 Axis M 710 IC 50H Arm Welding Machine , Articulated Mig Welder Boom Arm

Get Started Now 4 STEPS TO 5-AXIS SUCCESS 1 Choose a Machine or a Machine + Rotary • Define the size of your workpiece • Find a platter size to match • Select the right spindle speed. • Decide on the number of tools. 2 Pick Your Tools • Use the shortest tools possible • Use shrink fit holders for speeds above 10,000 rpm

CNC 5 Axis welding robot workstation KELITE WELD—Automatic welding

KP5-V2S2V five-axis positioner. The KP5-V2S2V five-axis positioner with two machining stations is available with payload capacities of 500 and 1,000 kilograms. It can be used to rotate and pivot components. As such, it facilitates ideal positioning and accessibility at all times, especially in the case of demanding tasks.

China 5 Axis Auto Welding Machine Manufacturers & Suppliers & Factory

The term "5-axis" refers to the number of directions in which the cutting tool can move. On a 5-axis machining center, the cutting tool moves across the X, Y and Z linear axes as well as rotates on the A and B axes to approach the workpiece from any direction. In other words, you can process five sides of a part in a single setup.

5 Axis M 710 IC 50H Arm Welding Machine , Articulated Mig Welder Boom Arm

Compact and highly accurate: With the TruLaser Cell 3000 5-axis laser processing machine you can cut and weld in two or three dimensions. Laser cutting machines Regardless of whether you need a CO2 or solid-state laser, we can offer the perfect 2D laser cutting machine to meet any requirement and can provide the ideal solution for any sheet.

Profibot® 5axis CNC Welding Robots Affordable premium quality

Machines are available in 4 and 5 axis configurations, with expandable machine beds and conveyor lengths to fit your business's unique layout. Learn More. Vernon Tool MPM; How to Choose. Operators can manually bevel pipes to create fittings that are already prepped for welding. The machine has two options for the length of the machine bed.

China 5 Axis Auto Welding Machine Manufacturers & Suppliers & Factory

The VARIAXIS series, simultaneous 5-axis machining center, are designed for high-speed and high-accuracy machining of multiple-surface. The VORTEX series are designed to machine large, complex workpieces such as aerospace components thanks to the ±40 degree tilting/rotary spindle. The VERSATECH series are designed to provide unsurpassed.

CNC Welding Machine India 5 Axis CNC Machinery Taylor Studwelding

Positioning accuracy of rotary axes (B) 0.02 °. Laser. Maximum laser power. 8000 W. Available lasers. TruDisk, TruFiber, TruDiode. The TruLaser Cell 3000 is a true all around compact 3D laser machine. It is well suited to laser welding, laser cutting, and laser metal deposition.

CNC 5 Axis horizontal rotary table welding robot workstation KELITE

CNC manufacturers and part programmers typically refer to '5-axis machining' only as a toolpath that requires all 5 axes to interpolate together to create a contour. The functions critical for successful '5-axis machining' are just as critical for any CAD/CAM generated toolpath on any machine with at least 1 rotary or orientation axis.

China 5 Axis Auto Welding Machine Manufacturers & Suppliers & Factory

MSM's NADCAP approved laser cutting and laser welding facility includes the newest 5 axis TRUMPF 7040 LASER. This machine utilises the very latest in "state of the art" industrial laser technology. Incorporated into a large working capacity and highly efficient production centre the TRUMPF 7040 is ideally suited to laser cutting and laser.

CNC 5 axis welding YouTube

The GG Series Five-Axis Machine. The GG Series Friction Stir Welding (FSW) machines are the most versatile heavy-section friction stir welders on the market. Capable of welding complex contours with power, precision, and rigidity far superior to any robot. This five-axis machine has been adopted by high-speed rail system manufacturers as the.

Cnc 5 Axis Welding Manipulator Automatic Welding Machine YouTube

CNC (Computer Numerical Control) machining refers to the process of removing material with high-speed precision machines that make use of a wide range of cutting tools. 5-axis machining refers to a machine's ability to move a tool or a part in five different axes simultaneously. Basic machining operates on three primary axes, X,Y, and Z.

Industrial Welding Robots 5 Axis Arc Welding Robotic Arm

Products Machines Milling 5-Axis Milling Gantry Series Gantry Series High Gantry Machines Highlights Gantry design machines for the dynamic 5-axes machining of large workpieces Various spindle versions for every application Perfect accessibility Technical data Max. X-axis travel 708.7 in. Max. Y-axis travel 177.2 in. Max. Z-axis travel 78.7 in.

China 5 Axis Automatic Welding Machine Manufacturers & Suppliers

laser cutting Sigma 5 Axis Laser Cutting System • Three dimensional cut paths • High speed, high precision • Fiber laser technology • Position based firing laser power control • Unique cutting features The flexible system configuration of a two axis rotary assembly, mounted to an XY stage, maximizes laser on-part accessibility, system simplicity, and tooling path efficiency for high.